by admin

Share

by admin

Share

STAY IN THE LOOP

Subscribe to our free newsletter.

Wind Tunnel Performance Verification

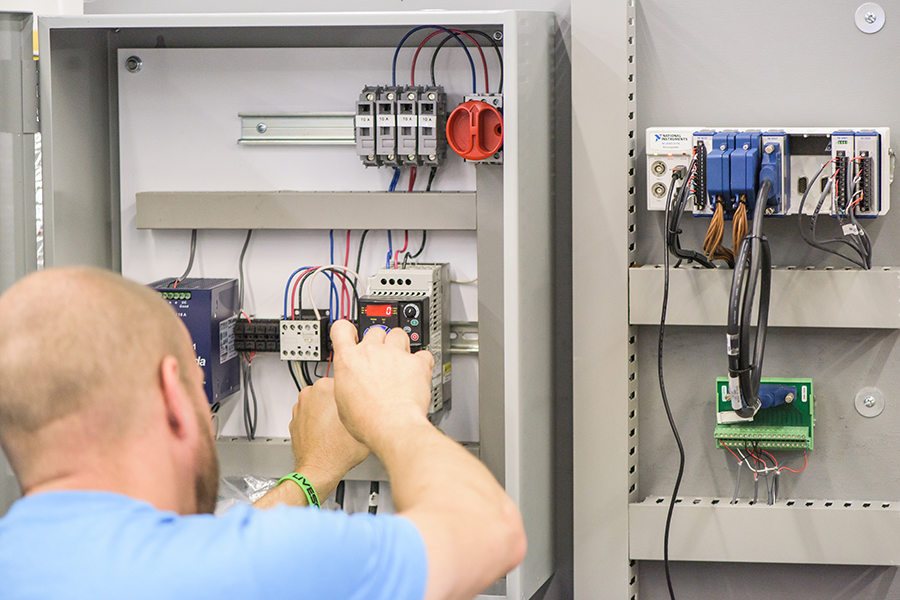

Our laboratory includes two temperature and humidity-controlled wind tunnels for the purposes of testing air-to-refrigerant heat exchangers. Testing can be provided to confirm performance data and/or to validate heat exchanger modeling assumptions using CoilDesigner® or other software. Testing can be done with hot water, chilled water, glycol or refrigerant.

Performance Verification

Our laboratory includes several environmental chambers for the purposes of testing individual components, novel technologies and full HVAC&R systems. Testing is conducted for a variety of purposes to accommodate differing research and development needs. System level testing capabilities are as follows:

- Multiple chambers available; indoor/outdoor rooms

- Chambers ranging in size from 7’ x 7’ x 7’ to 15’ x 15’ x 15'

- Up to 6-ton system capacity

- Temperature control: 20°F (-7°C) to 112°F (44°C) within +/- 2.0°F (1.0°C)

- Relative humidity control: 35% – 90%

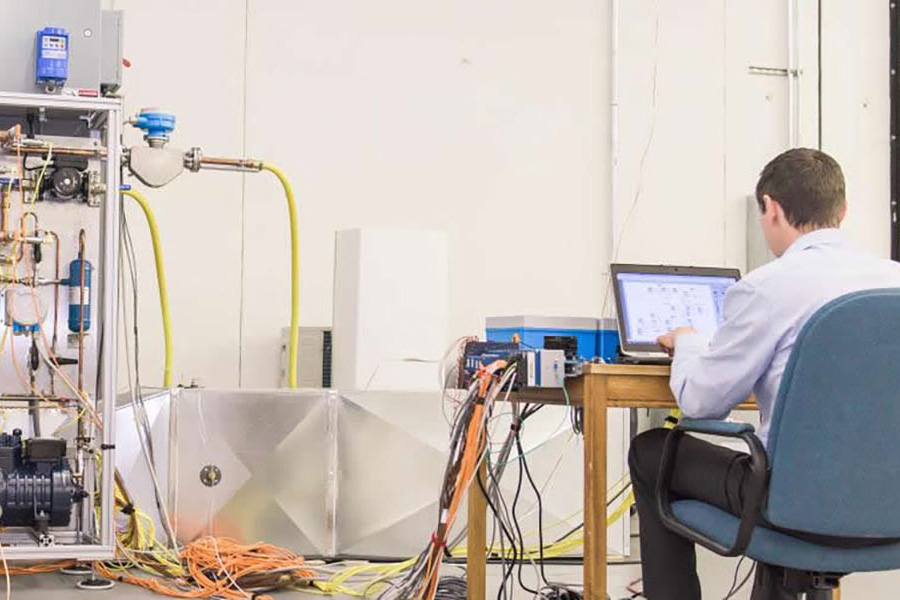

Measurement and Verification Support

When your system is ready to move out of the lab but not yet ready for full commercialization, OTS R&D is ready to help by providing third-party measurement and verification support. We can aid in finding site partners, installing sensor equipment in the field, and monitoring system performance using real-world operating data. Testing in the field is a vital step to finalizing a unit design and control sequence prior to full market release.