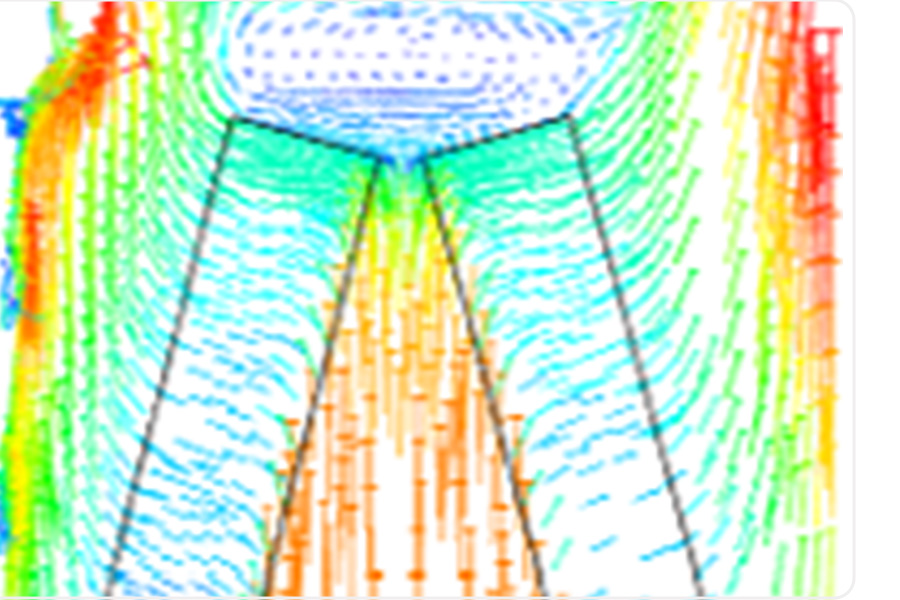

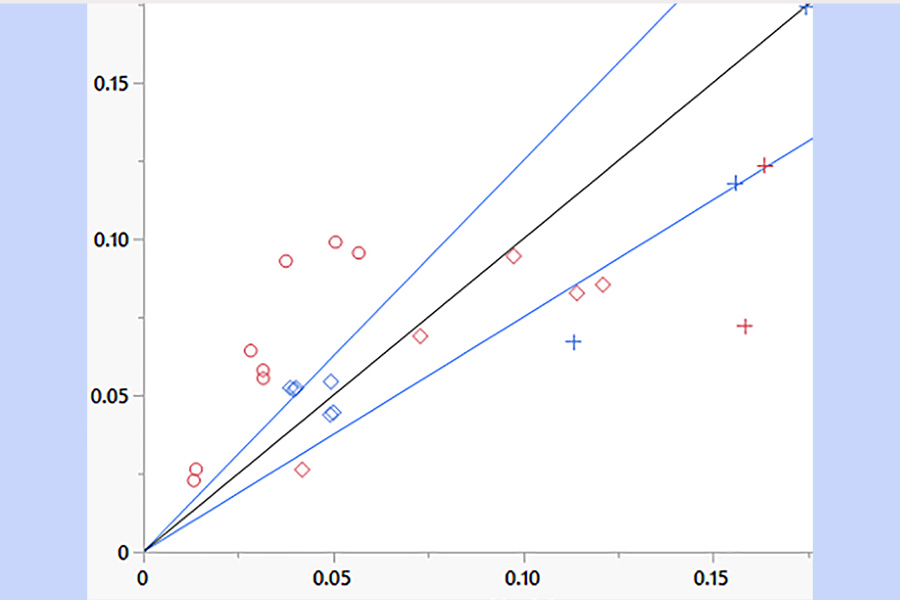

Flow Analysis and Geometry Optimization

Understanding fluid flow behavior and topology changes can be critical in addressing specific component or system challenges and identifying opportunities for improvement. Leveraging a variety of tools and approaches, the OTS team can model and analyze heat exchanger and system level fluid flows and optimize surfaces, shapes and passages to achieve greater performance.

Representative Projects