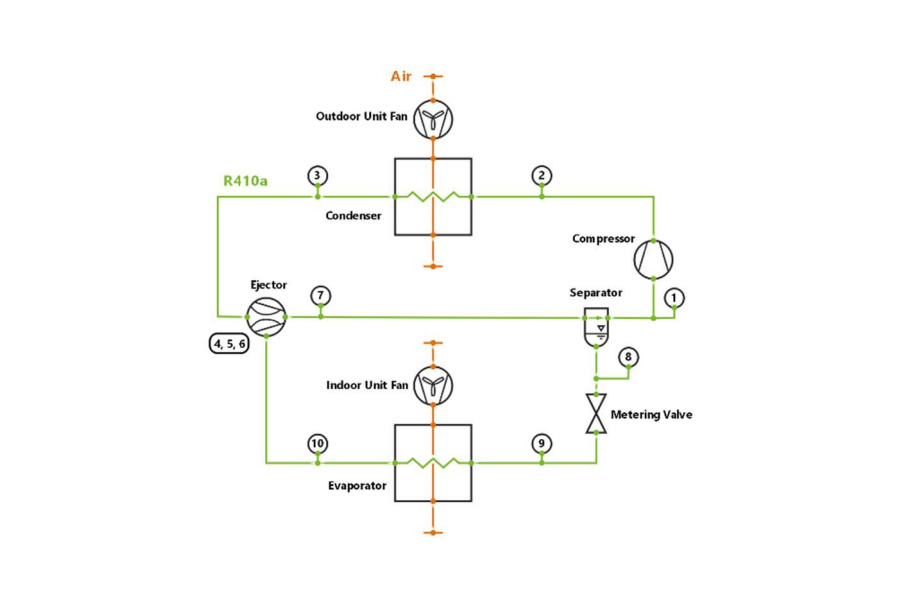

Evaluate unconventional system designs to understand their behavior and potential to compete with the status quo. Explore component choices for prototype development and future mass production.

“We are very proud to have been part of this project. . . . It was truly a symbiotic experience.”

“This project has been very helpful so far & looks to be very impactful to our future projects.”

“I speak for all us in how appreciative we are of your flexibility, efforts, efficacy, and kindness over the last 6 weeks or so. Not only do we feel that our novel system is validated by the results we saw at OTS, we feel validated as an engineering team. Much of that can be attributed to how well you worked with us. Thank you!”

"I just want to say thank you for sharing these thoughts. These recent emails have been some of the most valuable discussions yet. We’ve come to highly respect OTS R&D knowledge in heat transfer and thermal flows while working with you on this project over the past few months.”

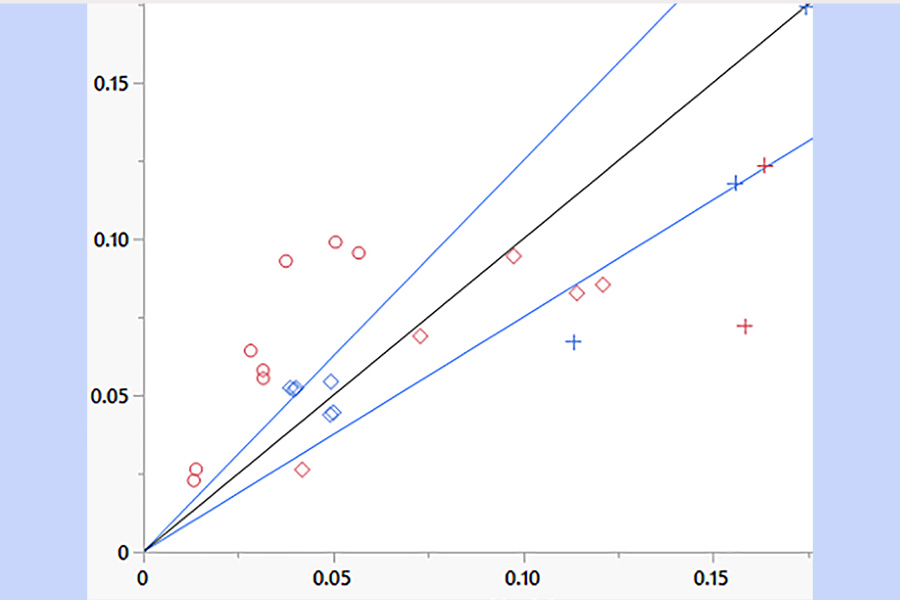

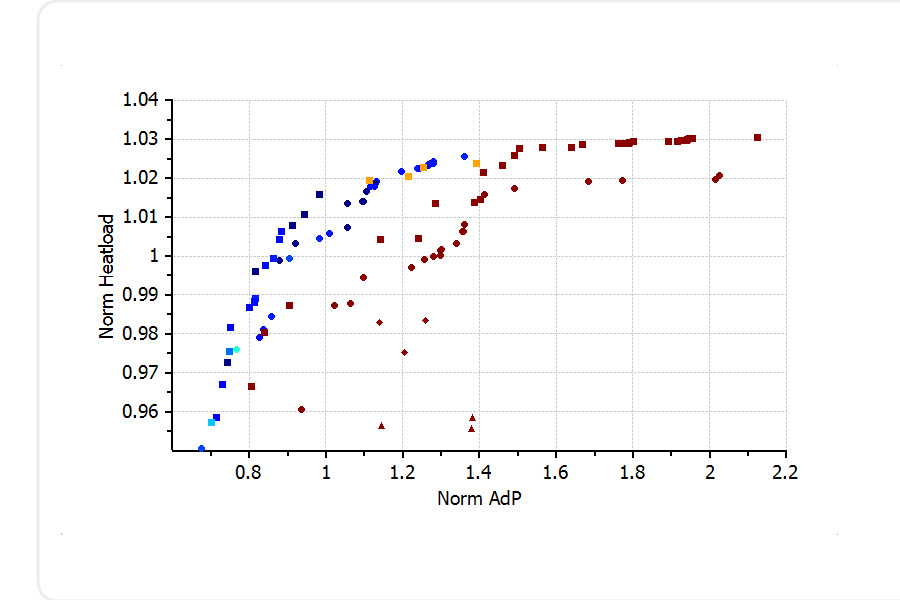

Improve the accuracy of heat exchanger models by developing a specific and comprehensive correlation accounting for the range of parameters accounted for in your specific design.

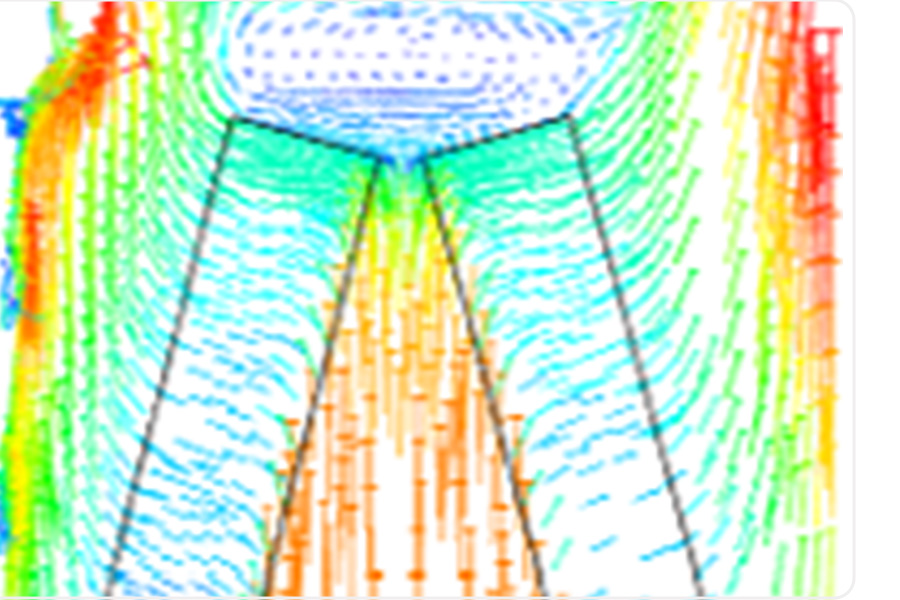

Understanding the severity and variation of maldistribution can be critical in assessing appropriate redesign choices to improve performance and reduce noise.

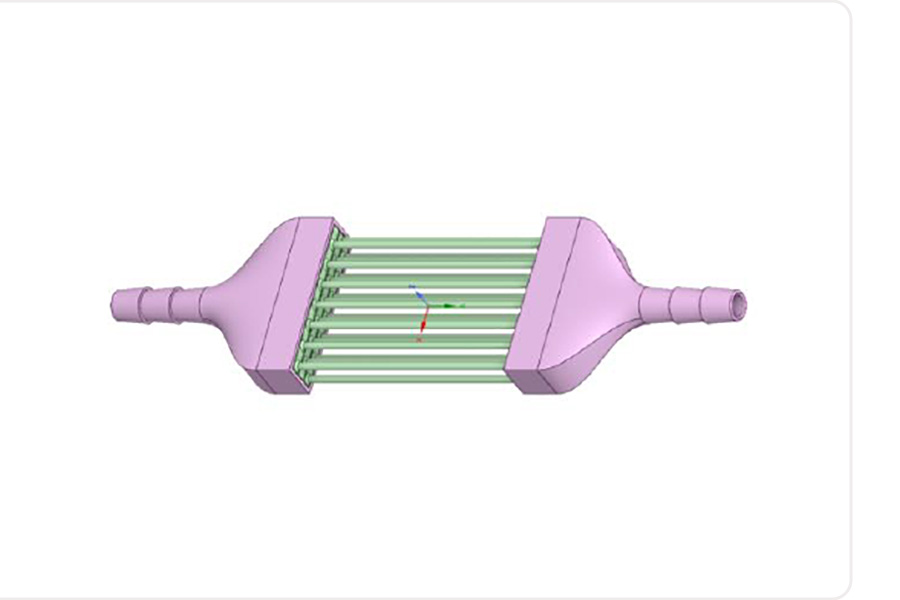

Knowing what improvements and changes to incorporate for a new fin design is critical when considering a capital investment for a new fin die. Assess a wide range of options including the impacts of tube diameter, fin thickness, spacing, slits and louver enhancements, and other novel features.

Sometimes a challenge calls for a novel solution, one a bit outside the box aiming to solve a very specific problem.

Evaluate thousands of possible design combinations to find the critical trade-offs and best possible solutions using in-house tools and genetic-based optimization algorithms .