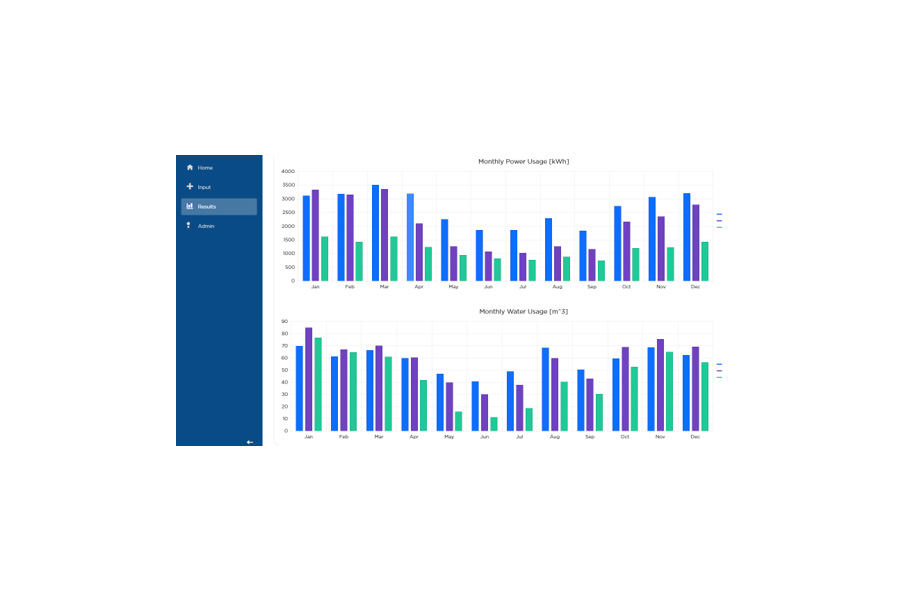

Comprehensive analysis of field data to understand system response, efficiency and overall performance.

Evaluate a new product through active demonstration in the field combining collected data and user feedback to assess market viability.

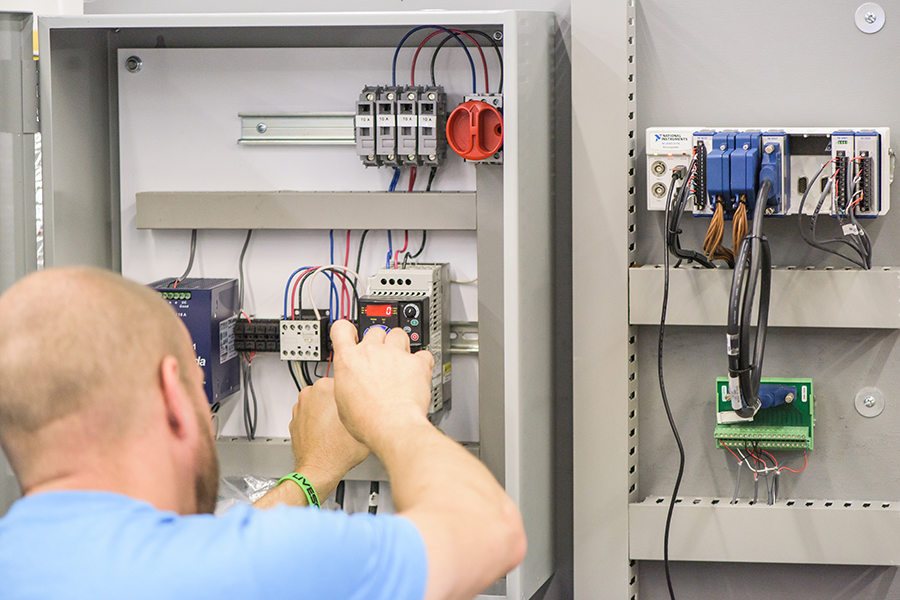

Install instrumentation in the field to collect real-world operating data to evaluate system performance.

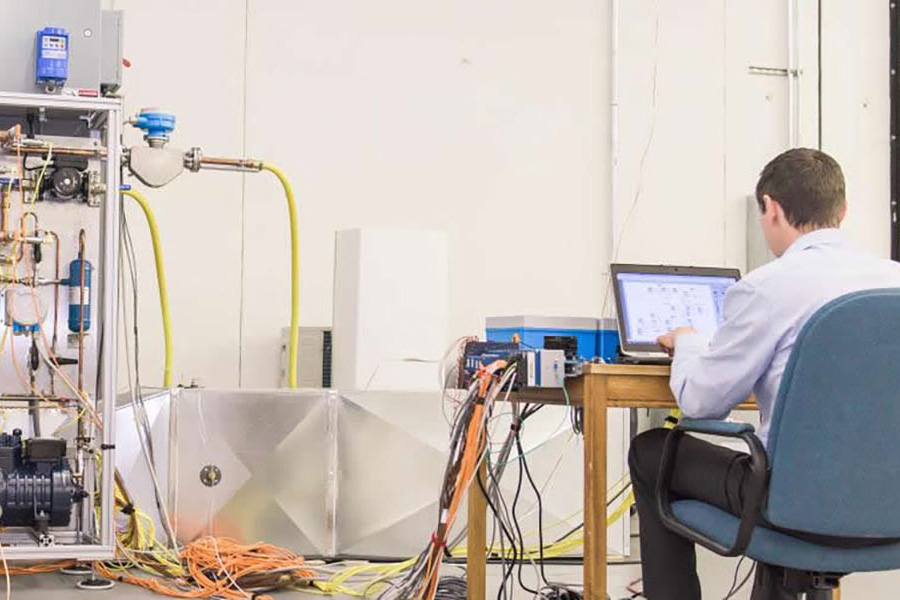

Design and construct custom test rigs for component and system evaluation. Nearly everything in the OTS R&D laboratory we designed and built ourselves – let us help you design and build a test rig for your facility!

Assemble custom prototypes for cooling and heating applications including novel refrigeration systems, non-vapor compression technologies, and/or advanced heat exchanger designs.

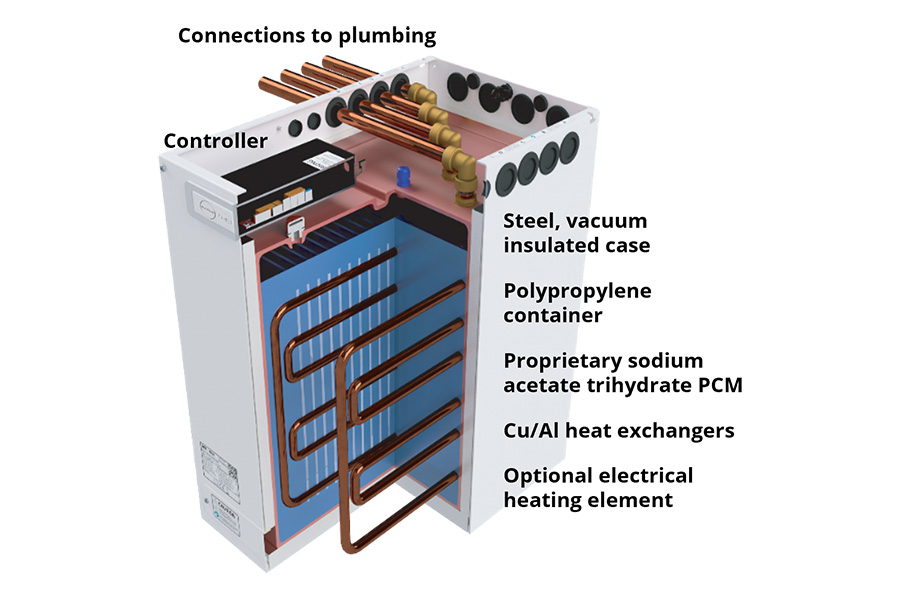

Design, simulate and analyze unique systems requiring careful thermal management. Leverage modeling tools to consider alternate components and find an optimized design.

Testing simulated faults to gather data on system response when approaching or experiencing component or total failure.

Evaluating the impact of a refrigerant replacement or refrigerant additive, such as an odorant to support detection of refrigerant leaks.

Testing across a wide range of conditions, including those per established standards, to determine system capacity and efficiency.

Derive 10- and 20-coefficient models with confidence, or expand the test matrix to reduce uncertainty at operating extremes.